What Intel Learned When an Elevator Smashed Its Supercomputer Chips – CNET [CNET]

Intel personnel were moving a bunch of the processors on a cart when a closing elevator door toppled it, Raja Koduri, leader of Intel’s Accelerated Computing Systems and Graphics Group, said at Intel’s Innovation conference Tuesday.

He didn’t say how many were ruined, but the loss stung because they were initial samples used to test performance and look for problems. “Every one of them at that stage is expensive,” Koduri said in an interview. With hundreds of manufacturing steps, it takes months to make a single advanced chip.

The elevator door wasn’t just a one-off bummer. It actually revealed a problem that stood in the way of Intel’s effort to reclaim its processor manufacturing leadership: human error.

Ponte Vecchio is a mammoth processor with more than 100 billion transistors, just about as many as anybody’s processor in the business. To make something that big, Intel used its advanced packaging methods to bring together 47 separate slices of silicon.

But that packaging relied on humans, carts and elevators that are much more fallible than the processes Intel typically uses to build chips.

Making Meteor Lake: More automation, fewer elevators

In contrast, Intel uses much more automation for the advanced packaging underlying its 2023 PC processor, code-named Meteor Lake. Meteor Lake’s elements, called chiplets, will be joined into a single processor at Intel’s new advanced packaging fabrication facility, or fab, near Portland, Oregon, Koduri said.

The Ponte Vecchio processor is designed to accelerate tasks like scientific calculations, graphics and artificial intelligence. It’s now formally named Intel’s Data Center GPU. Only the Aurora Supercomputer gets the processors now, but Intel plans to sell them more broadly starting in 2023, Koduri said. They compete chiefly against Nvidia’s new Hopper H100 graphics processing units.

Supercomputers are important, but Meteor Lake is more important to Intel’s fate. PC processors are one of the company’s biggest product lines, and rivals AMD and Apple have grown more competitive.

With Meteor Lake Intel builds some of the chiplets with its own new Intel 4 manufacturing process, a key step on the company’s effort to reclaim leadership lost to Taiwan Semiconductor Manufacturing Co. (TSMC) and Samsung.

But with an advanced packaging technology called Foveros, Intel also links those chiplets with others from TSMC. The advanced packaging methods let Intel advance some processor elements faster while cutting costs on others.

Ponte Vecchio uses Foveros and another Intel packaging technology called EMIB. Where Foveros stacks chiplets one atop another like pancakes, EMIB links their edges side to side with high-speed links. EMIB is key to another Intel processor — its Sapphire Rapids chip coming to servers in 2023.

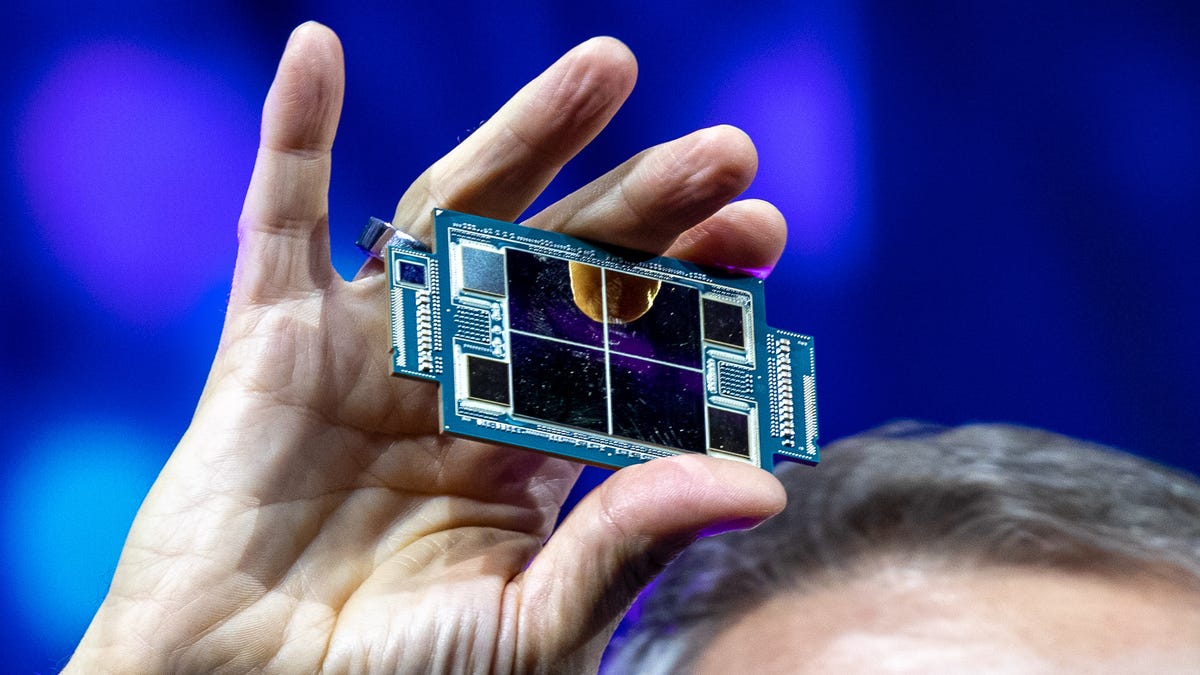

Intel CEO Pat Gelsinger holds a Sapphire Rapids server processor, showing how it’s made of eight “chiplets.” The four central tiles house processing cores and the four smaller rectangles are high-bandwidth memory.

Stephen Shankland/CNETIn designing Ponte Vecchio, Intel expected troubles with packaging. But the company was surprised with how smoothly it worked.

“The thing that we were most worried about was advanced packaging,” but the 47 chiplets went together smoothly, Koduri said in a press conference. The problems came from mundane problems like a bug in the PCI Express communications system.

That result helped convince Intel it could employ advanced packaging for a critical processor like Meteor Lake.

“It gave us a lot of confidence for higher volume products to do advanced packaging,” Koduri said.

![what-intel-learned-when-an-elevator-smashed-its-supercomputer-chips-–-cnet-[cnet]](https://i0.wp.com/upmytech.com/wp-content/uploads/2022/09/88655-what-intel-learned-when-an-elevator-smashed-its-supercomputer-chips-cnet-cnet.jpg?resize=800%2C445&ssl=1)

![1099-k-irs-tax-delay:-what-last-minute-filers-who-use-paypal-and-venmo-need-to-know-–-cnet-[cnet]](https://i0.wp.com/upmytech.com/wp-content/uploads/2024/04/178468-1099-k-irs-tax-delay-what-last-minute-filers-who-use-paypal-and-venmo-need-to-know-cnet-cnet.png?resize=300%2C169&ssl=1)

![prime-day-deal:-this-magsafe-iphone-stand-wallet-is-still-on-sale-–-cnet-[cnet]](https://i0.wp.com/upmytech.com/wp-content/uploads/2023/10/146949-prime-day-deal-this-magsafe-iphone-stand-wallet-is-still-on-sale-cnet-cnet.jpg?resize=300%2C169&ssl=1)

![ps5-and-xbox-series-x-backward-compatibility:-everything-we-know-as-new-consoles-launch-–-cnet-[cnet]](https://i0.wp.com/upmytech.com/wp-content/uploads/2020/11/15217/ps5-and-xbox-series-x-backward-compatibility-everything-we-know-as-new-consoles-launch-cnet-cnet.jpg?resize=300%2C205&ssl=1)